- Lectern

- Desktop Socket

- Motorized Retractable Monitor

- Conference Multimedia Terminal

- Motorized Foldable Conference Solution

- Portable Integrated Conference Multimedia Terminal

- High-end Digital Podium

- Round Type Desktop Socket

- Motorized Foldable Monitor

- Motorized Foldable Microphone

- Rectangle Type Desktop Socket

- Portable Integrated Tablet Solution

Portable Hospital GMP Turnkey Project Pharmaceutical PVC Soft Bag Making Filling and Sealing Assembly Machine

Basic Info.

| Condition | New |

| Warranty | 1 Year |

| Transport Package | Cartons; Wooden Case; |

| Specification | 3.2 x2.5 x2.5M |

| Production Capacity | 2 PCS/Year |

Product Description

Portable Hospital GMP Turnkey Project Pharmaceutical PVC Soft Bag Making Filling and Sealing Assembly Machine

IVEN Pharmatech is the pioneer supplier of turnkey plants that provides integrated engineering solution for worldwide pharmaceutical factory such as IV solution, vaccine, oncology etc., in compliance with EU GMP, US FDA cGMP, PICS, and WHO GMP.

We provide the most reasonable project design, the high quality equipment and the customized service to different pharmaceutical and medical factories from A to Z for Non-PVC soft bag IV solution, PP bottle IV solution, Glass vial IV solution, Injectable Vial & Ampoule, Syrup, Tablets & Capsules, Vacuum blood collection tube etc.

What does IVEN Non-PVC soft bag IV solution turnkey project include:

Core Description

IVEN's integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers' individual requirements, IVEN customizes engineering solutions meticulously for users on:

*Pre-engineering consulting service

*Production process selection

*Equipment model selection and customization

*Installation and commissioning

*Validation of the equipment and process

*Production technology transferring

*Hard and soft documentation

*Training for skilled workers and so on.

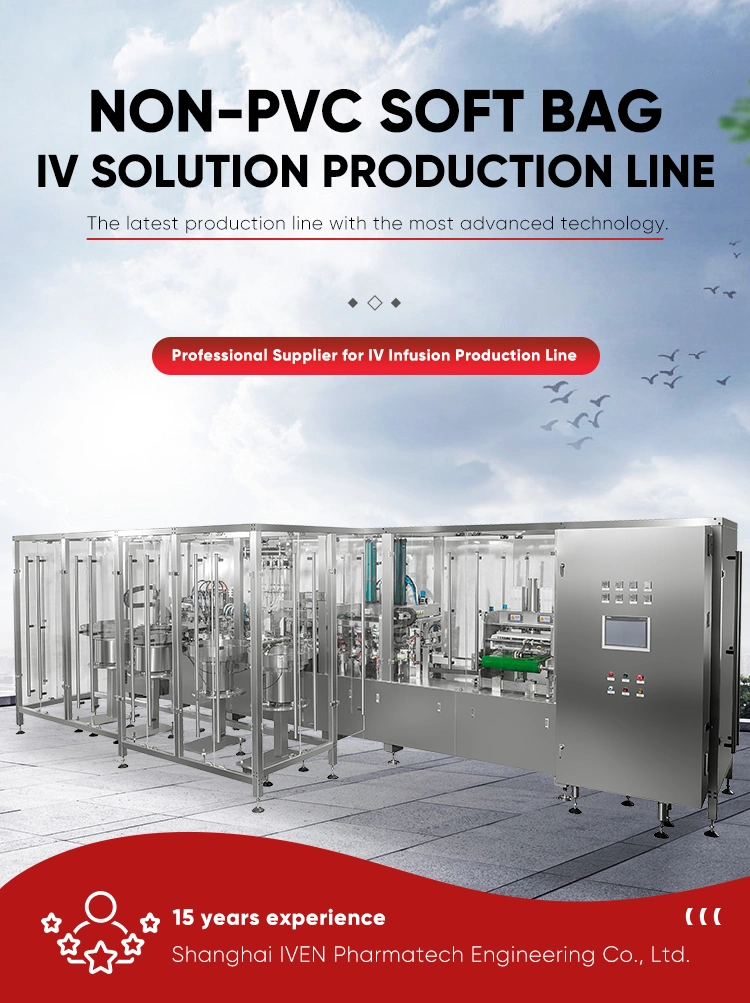

Main advantages of IVEN Non-PVC soft bag IV solution production line:

* 100% film utilization: no waste edge between every two IV bags, reducing both material and energy consumption.

* Reliable heating and welding system: Make sure the leakage rate for IV bags less than 0.03%.

* Quick changeover: Only need 0.5-1 hour to switch from one IV bag size to another.

* Compact structure, reduce 1/3 length of the machine, save room space and running cost.

* Stable running and transmission system: use combo-port design, only need 1 control system, 1 HMI and 1 operator.

* Safe filling nozzle: Adopt patent contact filling, no solution overflows, no particles generation during IV bag filling process.

* Auto detection and faulty rejection system to reject the unqualified IV bags automatically after cap welding.

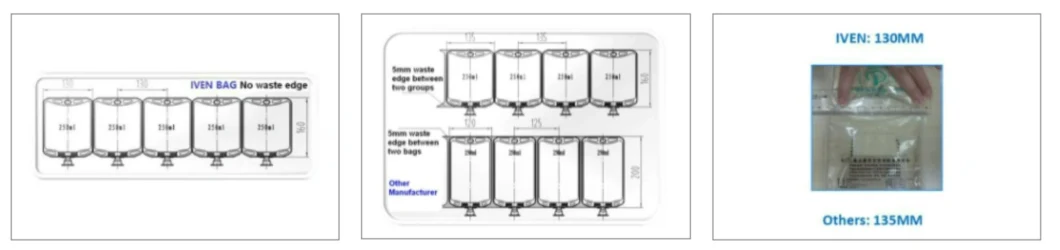

Cost saving of IVEN patent designed IV bags:

a.Special IV bag design with width of 130mm, one IV bag can save 10mm film than other suppliers.

b.No wasted edge between IV bags and groups, 100% film utilization.

c.Can save 250 iv bags more per roll of film than others with width of 135mm

Till now, we've already provided hundreds sets of pharmaceutical equipment and medical equipment to more than 50 countries.

Meanwhile, we helped our customers to built 20+ pharmaceutical and medical turnkey plants in Russia, Uzbekistan, Tajikistan, Indonesia, Thailand, Saudi, Iraq, Nigeria, Uganda, Tanzania, Ethiopia, Myanmar etc, mainly for IV solution, injectable vials and ampoules. All these projects won our customers and their government high comments.

We also exported our IV solution production line to Germany.

IVEN Non-PVC soft bag IV solution turnkey plant can supply you different types of bag designs:

Tech Parameters

| Model | Srd1a | Srd2a | Srd3a | Srd4a | Srd6a | Srd12a |

| Production capacity (500 ml) | 900 bph | 2000 bph | 2800 bph | 3600 bph | 5000 bph | 8000 bph |

| Power source | Ac 380 v 50 hz | |||||

| Power (kw) | 8 | 22 | 26 | 32 | 32 | 60 |

| Compressed air pressure | Dry and oil-free compressed air pressure is ≥ 0.6 mpa, the cleanness is 5 μm. The machine will automatically warn and stop when the pressure is too low | |||||

| Compressed air consumption (l/min) | 1000 | 2000 | 2500 | 3000 | 4000 | 7000 |

| Clean air pressure | The pressure of clean compressed air is ≥ 0.4mpa, the cleanness is 0.22μm | |||||

| Clean air consumption (l/min) | 500 | 800 | 900 | 1000 | 1200 | 2000 |

| Cooling water pressure | >0.5kgf/cm2 (50kpa) | |||||

| Cooling water consumption (l/h) | 100 | 300 | 350 | 500 | 400 | 800 |

| Nitrogen consumption | According to the customer's special requirements, can use the nitrogen to protect the machine, the pressure is ≥ 0.6 mpa. The consumption is ≤ 45 l/min | |||||

| Running noise | <75 db | |||||

| Room requirements | Environment temperature: ≤26ºC; humidity: 45%-65%, max. humidity ≤ 85% | |||||

| Overall size (m) | 3.26*2.0*2.1 | 4.72*2.6*2.1 | 5.52*2.7*2.1 | 6.92*2.7*2.1 | 8.97*2.7*2.25 | 8.97*4.65*2.25 |

| Weight (ton) | 3 | 4 | 5 | 6 | 8 | 12 |